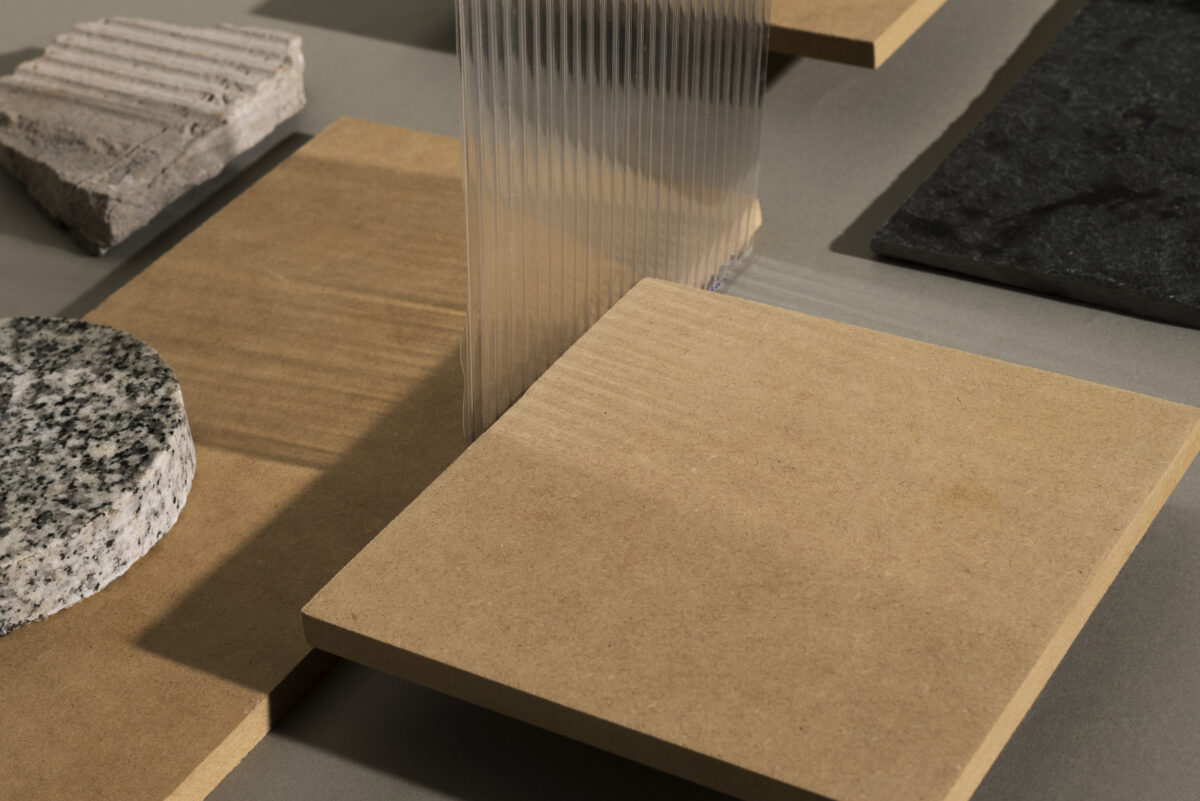

For some DIY enthusiasts, power saws can be too overwhelming to use. If not used properly, it can easily break medium-density fiberboard (MDF), causing you to waste the material.

Here, I will share some tricks I have learned over the years on how to cut an MDF board without a saw. Using simple hand tools, you can make precise cuts in your MDF for any home improvement project.

How to Cut an MDF Board Without a Saw

If you don’t have saws, you can still cut MDF boards using tools such as utility knives, miter shears, rasps, and routers. However, you need to select the appropriate tool depending on the board’s thickness, as well as the size, length, and angle of the cut you’re trying to achieve.

Medium-density fiberboard is a versatile and widely used material for home improvement and woodworking applications. Even without power saws, you can use other household tools to cut them.

Cutting MDF Boards Using a Utility Knife

While power saws are ideal for making straight, quick cuts in MDF, a utility knife can also be used to make precise, detailed cuts if done correctly. With the proper technique, simple tools can cut and shape different types of medium-density fiberboard accurately. Here is how to do it:

- Gather your materials: MDF board, utility knife with fresh blade, metal straightedge, pencil, and sandpaper.

- Measure and mark your cut lines on the board using the straightedge and pencil. Mark the waste side of cuts.

- Position your straightedge along the cut mark to guide the knife. Make multiple passes along the cut, applying firm downward pressure with the knife.

- Cut slowly on the first pass, about 1/4 inch deep. Subsequent passes should be lighter as you cut through the board.

- For curves, use the straightedge as a guide. Lift and pivot the knife slightly. Use smooth, continuous motions.

- Sand cut edges to smooth any rough areas after cutting is complete.

Cutting boards with a utility knife works for straight or curved cuts. It gives you greater precision yet is primarily practical for those 1/2-inch or thinner. Any thicker and cutting through the entire depth becomes quite tricky. Fiberboard is mostly dense to cut than thin plywood without saw.

Cutting MDF Boards Using a Rasp

The coarse teeth of a rasp allow you to rub away material to cut notches, curves, and other designs in a medium-density fiberboard. With some finesse, a rasp gives you hands-on control for detailed shaping work. Here are the steps for getting that:

- Select a coarse-toothed wood rasp. Look for a crosscut or curved rasp, depending on your desired cut.

- Draw the desired shape on the MDF with a pencil. Make stop-cuts at the shape’s corners with a utility knife.

- Begin rasping with firm, even pressure along the cut line, removing a little material with each pass.

- Work methodically for smooth edges. Let the rasp do the cutting; do not force it.

- Use a finer rasp and sandpaper to smooth cut edges once complete.

- Clean rasps frequently as MDF dust accumulates. An old toothbrush helps remove debris from the rasp’s teeth.

One advantage of using a rasp to cut fiberboard is the ability to shape the material by hand. The coarse rasp teeth abrade the soft material quickly yet allow for controlled, nuanced curves that would be hard to achieve with other tools. You can also check on cutting angles with a circular saw.

Cutting MDF Boards Using Miter Shears

Crafters use miter shears for basic MDF cutting tasks. Shears provide a fast, inexpensive option for those without power saws.

With the correct technique, miter shears can provide an easy manual cutting, like cutting a quarter-round molding without a saw. Here are the steps to trim fiberboards using shears:

- Select handheld shears designed for cutting sheet metal or lightweight wood/plastic. Avoid paper shears.

- Measure and mark cut lines on the board with a pencil, ruler, or template.

- Position shears along marked cut lines on the fiberboard supported on a cutting mat or wood surface.

- Cut using smooth, even pressure, allowing the shears to do the work. Do not force.

- Make curved cuts by pivoting the shears while cutting. Use short, overlapping snips.

- For clean cuts, avoid changing the shears’ direction mid-cut. Start new cuts from an edge.

- Sand cut the edges to remove rough areas or fibers.

Shears are best for cutting thin MDF boards and pegboard without saw. The manual nature gives excellent control for following curves and lines. Cuts may be rougher than saws, so sanding is essential for smooth finished edges.

Cutting MDF Boards Using a Router

A router is a versatile power tool that can make clean, precise cuts through fiberboard. With the right router bit and careful handling, routers provide an efficient method for making straight and curved cuts in medium-density fiberboard. Here is how to put routers to work on fiberboards:

- Select a sharp, carbide-tipped straight or spiral flush-trim router bit appropriate for MDF. Install in the router.

- Clamp the board to a work table. Use a straightedge guide for straight cuts.

- Set router bit cutting depth just above fiberboard thickness. Make multiple light passes to cut gradually.

- Feed the router along cut lines, pressing it firmly to the guide. Move right to the left.

- For curves, guide the freehand router gently along pencil lines. Use gradual, sweeping motions.

- Finish cuts by sanding to remove splinters. Vacuum to remove excess dust.

Routers allow for great precision when cutting MDF, especially with the aid of a straightedge. The spinning router bit provides smooth, splinter-free edges, while the motorized tool does the hard work. It is highly versatile material to trim laminate without a router.

Pieces can be trimmed to perfect dimensions or shaped with carved details. With the right technique, routers give woodworkers flexibility in complex MDF cutting applications. However, they do require skill and router-specific safety know-how to operate safely.

Cutting MDF Boards Using a Dremel

Dremels and other small rotary tools are versatile in making detailed cuts and shapes in medium-density fiberboard. Its compact size and maneuverability allow precision curve cutting and detail work that may be difficult with full-size tools.

Follow these steps when using a Dremel:

- Select an appropriate Dremel cutting or reinforced cutoff wheel for wood/plastic.

- Trace the desired pattern or lines on the MDF with a pencil. Clamp the workpiece firmly.

- Allow the Dremel tool to reach full speed before contacting the fiberboard. Use light pressure.

- Guide the rotating wheel along cut lines. Do not force it.

- Make several shallow passes to cut gradually through the board.

- Use low speeds and sanding drums for smoothing cut edges and curves.

Dremels are ideal for detailed, freehand cutting applications where control and precision are critical. Their small size allows you to maneuver the cutting wheel over the workpiece for curves, holes, or unique shapes.

Related Questions

What Is the Best Tool to Cut an MDF Board?

A circular saw with a carbide-tipped blade is the best tool to cut an MDF board. Circular saws are designed for cutting through thick materials, and carbide-tipped edges are sharp and durable enough to make clean cuts in medium-density fiberboards.

What Is the Easiest Way to Cut MDF Boards?

Using a table or circular saw designed for cutting wood is the easiest way to cut MDF boards. It’s best to use sharp carbide-tipped blades to prevent chipping the board.

Can You Use Regular Scissors to Cut Medium-Density Fiberboard?

It is possible to cut fiberboards with regular scissors, yet it is not recommended. Compared to miter shears, regular scissors are not designed for cutting through thick materials like medium-density fiberboards and will not produce a clean cut.

Conclusion

While saws make cutting medium-density fiberboard faster and easier, the methods described here enable you to achieve the same high-quality results using basic hand tools. With the right technique, you can cut any shape or thickness of MDF boards cleanly and precisely.