Say you need an air compressor; the logical step would be to research available air compressors. However, you may encounter a massive amount of information with most articles using buzzwords such as gas and electric compressors.

In this article, I seek to inform you of the characteristics of gas vs electric air compressor. I hope this information will help you decide on the compressor that fits your needs.

Contents

Gas vs Electric Air Compressor

Before you decide on an air compressor, I’d love to share some insights on the main differences between electric and gas-powered ones. Gas vs electric air compressor? Read below and you’ll know which is best for you.

Gas Air Compressors

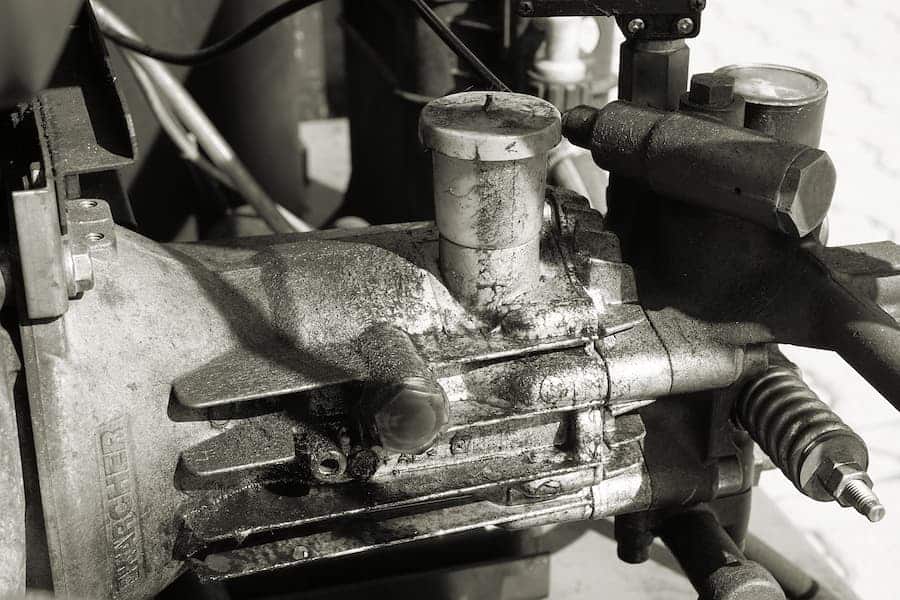

Gas air compressors are mechanical devices that increase the pressure of a gas by reducing its volume. The pressurized gas can then power all sorts of tools. A gas air compressor is typically made up of two parts:

- An air end

- An engine

The air end sucks in the air into the compression chamber to compress the air by forcing it into a compact place. The gas engine converts gasoline into motion, forcing the air end to move and consequently compress air.

Electric Air Compressors

Electric air compressors function in a similar way to their gas counterparts. However, in this case, an electric motor replaces the gas engine. The electric motor helps in the compression of air leading to the eventual pressuring of the said air.

Similarities and Differences

Let’s look at the similarities and differences between gas and electric air compressors. I will highlight the comparisons by placing them under specific topics.

Similarities

When it comes to function and power output, gas and electric air compressors have a couple of aspects in common.

Function

Both types of air compressors function similarly. Air compressors force air into a container and pressurize it. The air then passes through an opening in the tank, where pressure builds up.

The pressurized air powers tools such as paint sprays and roofing guns.

Power Output

Power outputted by the two compressors roughly stands at the same level with the same tank capacities, despite the different power sources.

However, should you choose, you can opt for larger heavy-duty gas-powered air compressors, which provide more power for more strenuous jobs.

Differences

Power Source

As you might have guessed, the main difference between electric and gas-powered air compressors comes from their power sources. Electric air compressors get their power from electricity, while gas-powered air compressors depend on gasoline or natural gas for their power to function.

| Electric | Gas | |

|---|---|---|

| Power Source | Powered by electricity, requiring a power outlet or generator. | Powered by gasoline or natural gas. More portable but heavier due to its engine. |

| Operational Duration | Shuts down occasionally when air pressure drops below threshold. | Functions longer, producing a steady level of air. |

| Price and Operational Cost | Cheaper due to electricity being a cheaper power source and compact design. No recurring fuel cost. | More expensive due to its engine and components. Has a recurring cost for fuel. |

| Noise | Quieter, usually with a maximum sound level of around 60 dB. | Louder, with noise levels starting from 75 dB due to combustion engines. |

| Environmental Impact | Less environmental impact due to no emissions. Powered by electricity. | Emits harmful gases like carbon monoxide and dioxide. Not safe for confined spaces. |

Typically, electric air compressors require a nearby power outlet to function. Such a requirement is not an issue as most jobs requiring an air compressor usually occur indoors.

Lack of an indoor electricity supply does not impede as you could use a generator to provide the electricity to power your electric air compressor.

Gas air compressors solve the issue of power, especially in remote areas of your locality. Since these air compressors only require gasoline to function, they end up being the most portable of the two.

However, the gas air compressor’s engine makes the compressor heavier compared to the electric counterpart, hindering the portability of the compressor.

Operational Duration

Gas air compressors tend to function for longer as they produce a steady level of air. On the other hand, electric air compressors shut down occasionally when the air pressure level drops below the threshold levels.

Price and Operational Cost

Any prospective buyer might consider a major factor before buying an air compressor is the price. The electric air compressor is cheaper overall compared to its gas counterpart.

Electric air compressors tend to be less pricey as they tend to use cheaper technology with smaller and more compact designs.

This pricing also comes from using electricity as its power source, which is considerably cheap. In contrast, gas-powered air compressors utilize heavier engines that require more components.

You should consider that added to the initial purchase; a gas compressor features the recurring cost for fuel which is quite expensive.

In some cases, you may find that an electric compressor costs up to half the price of a gas-powered compressor.

This price discrepancy comes down to the portability and usability of a gas air compressor in situations or areas that might render an electric compressor useless, such as in remote areas.

Noise

Noise levels from an air compressor, ranging from 40 to 100 dB, should be a concern to you, especially if you plan on working with it for long periods.

Despite both being air compressors, electric compressors tend to be a lot quieter than gas-powered air compressors.

Electric air compressors produce little noise, usually producing a maximum sound level of around 60 dB.

Advancing technology regarding motor design might contribute to such low levels of noise, allowing for regular use of this compressor without experiencing adverse effects.

In contrast, gas-powered air compressors produce high amounts of noise, with a minimum level of 75 dB.

You can trace these high noise levels to gas compressors possessing combustion engines with more moving mechanical parts.

Repeated exposure to such noise levels might cause temporary hearing loss and, in extreme cases, permanent loss of hearing ability.

Environmental Impact

Electric air compressors produce a lesser environmental impact compared to gas air compressors. The lower environmental impact is attributed to electricity as a power source hence no opportunity to produce harmful waste gases.

On the other hand, gas compressors produce carbon monoxide and dioxide, and other gases, which might harmfully damage the atmosphere and ozone layer.

The emission of harmful gases prevents the usage of gas air compressors within confined spaces as they might cause severe health complications, such as suffocation.

When to Use an Electric Air Compressor

Electric air compressors are best suited for roofing, this is a small to medium-duty job, and for DIY projects at home. It is also preferred in indoor situations as it does not produce any gases and is relatively quiet.

When to Use a Gas Air Compressor

Should you have a task that requires an air compressor in a remote area, a gas compressor is your best bet. As long as you have gasoline, you can use this compressor in any setting as long as it is in a ventilated area.

The gas compressor is also suitable for heavy-duty jobs that an electric compressor cannot handle.

Final Verdict

After numerous comparisons, consider that you should try out the electric compressor as a beginner. The electric compressor provides enough power to power your tools as you work on your indoor projects. This compressor is relatively easy to use and cheap as it only requires electricity to function.

The electric compressor is perfect for indoor projects as it is relatively quiet and smoke-free. However, I recommend you try out a gas compressor for more power-intensive jobs.