With DIY projects that require air pressure, you may be at a crossroads about whether you need air compressors or air tanks. While they share some similarities, their differences weigh heavily regarding their applications, and not choosing the right one for your project can be costly.

I’ve used these machines for most of my DIY projects over the years. I’m sharing the unique features of an air compressor vs air tank and how to determine which tool best suits your needs.

Contents

Air Compressor vs Air Tank

Before we dive deeper into their similarities and differences, I’d like to give you a brief overview of the differences between these two significant tools in the DIY space.

Air Compressor Overview

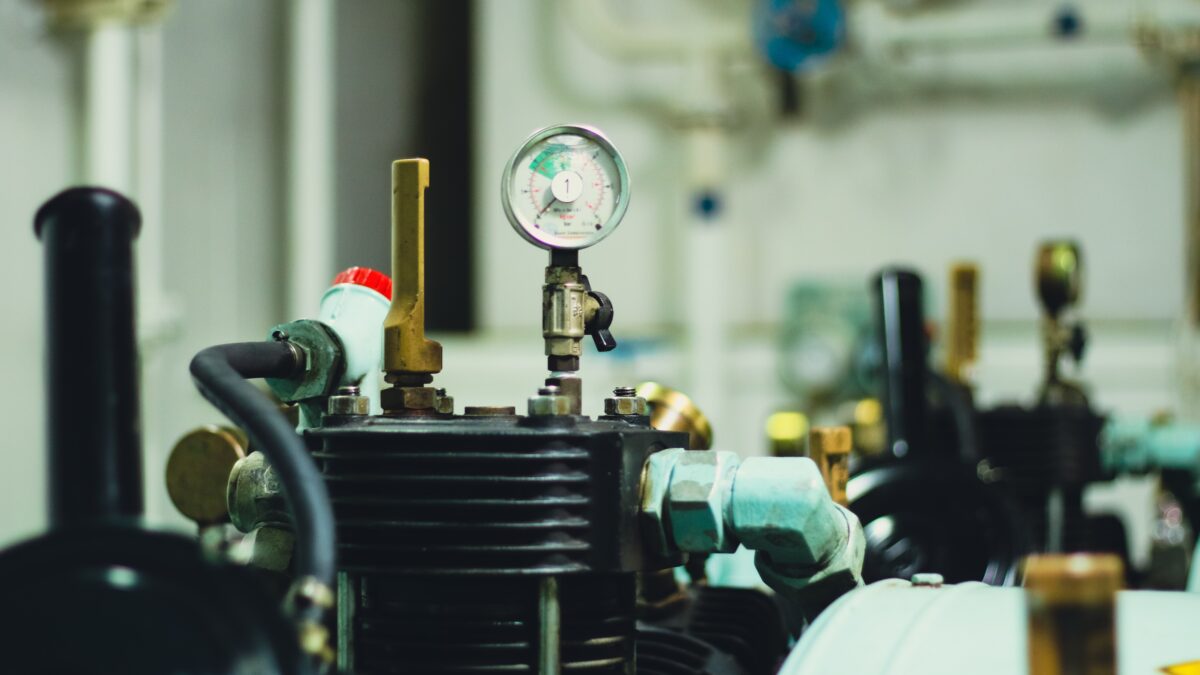

As the name suggests, air compressors are mechanical devices that compress air and supply it to power pneumatic tools. They function by converting electrical energy into potential energy stored as pressurized air.

This machine gathers atmospheric air and compresses it. Afterward, it stores that air in a tank at higher pressure. This compressed air gets released suits long-term projects with high air consumption, like inflating tires or powering air tools.

Air Tank Overview

On the other hand, air tanks store pre-compressed air and act as a portable solution for inflating tires, running small tools, or providing a quick burst of air. They are compact and easily transported, yet they need the capability to compress air independently.

The primary purpose of an air tank is to store compressed air, which you can use for various applications. For example, this helps me deliver a constant supply of air when I use tools like nail guns, paint sprayers, or air ratchets.

Air tanks excel at tasks requiring a limited amount of air. However, since air tanks don’t compress air, you’ll need a compressor to fill them. Despite that, they are great additions to any DIY project setup, especially for inflation tasks or powering pneumatic tools.

Comparing Air Tanks and Air Compressors

Learning the similarities and differences between air compressors and air tanks is essential for choosing the right tool for your specific needs.

Features

Understanding the unique features of both tools helps determine the right option for your project. Consider factors like size, functionality, and portability when choosing between an air tank and a compressor.

| Machine | Capacity | Best For | Application |

| Air compressor | Continuous supply of compressed air | higher volume and pressure of air | Powering pneumatic tools |

| Air tank | Finite capacity of air | Quick bursts of air | Inflating tires and small items |

Similarities

In a nutshell, both devices provide compressed air for various tasks. Some critical similarities between the two include the following:

- Providing compressed air

- Being used in similar applications

- Requiring routine maintenance

Differences

Despite their similarities, there are notable differences between a tank and a compressor.

Capacity

When it comes to capacity, air compressors can provide a continuous supply of compressed air. Meanwhile, air tanks have a finite capacity. You also need to refill them once depleted.

Applications

While both are used in similar applications, compressors are more versatile due to their continuous supply, making them ideal for running air-powered tools, inflating tires, or painting.

In comparison, tanks are perfect for occasional use when a portable and easily accessible air supply is needed.

Maintenance

Compressors require more maintenance due to their engines or motors, which need oil changes and filter replacements. I also invest in the best air compressor filter dryer to remove moisture and avoid rust buildup.

Air tanks, being simpler in design, require less maintenance overall. However, they still need regular inspection for leaks or damage.

Size

The size of air compressors is mainly determined by their CFM (cubic feet per minute) capacity, PSI (pounds per square inch), and HP (horsepower). Compressors with around 90 PSI and 4-5 CFM are adequate for most DIY tasks.

However, you might need a larger CFM or HP for heavy-duty applications like sandblasting or high-capacity pneumatic tools. Matching the tank size with the compressor output is crucial to ensure consistent airflow and meet peak demand.

Meanwhile, tanks come in different sizes, and the right choice depends on compressor capacity, tool usage, and your project demands. It’s essential to select the right size for your projects. Here’s a brief list of the standard capacities:

- Small: 3-10 gallons (My pro tip: Three to five gallons of air storage capacity per CFM output is a good rule of thumb for optimal performance.)

- Medium: 11-30 gallons

- Large: 30+ gallons

Portability

Thanks to its smaller size, a tank is generally lighter, more compact, and easier to transport. Meanwhile, a compressor tends to be bulkier and heavier due to its engine and internal components. This makes air tanks a more portable option for my on-the-go DIY projects.

Cost

I’ve found that compressors are generally more expensive due to their complexity and ability to generate compressed air. On the other hand, tanks are more affordable because of their simpler design.

| Criteria | Air Compressor | Air Tank |

|---|---|---|

| Capacity | Provides a continuous supply of compressed air. | Has a finite capacity and needs refilling once depleted. |

| Applications | Versatile with continuous supply, ideal for air-powered tools, tire inflation, and painting. | Best for occasional use requiring a portable and easily accessible air supply. |

| Maintenance | Requires more maintenance due to engines or motors (oil changes, filter replacements). Beneficial to have an air compressor filter dryer for moisture removal. | Simpler design leading to less maintenance. Still needs regular inspection for leaks or damage. |

| Size | Determined by CFM, PSI, and HP. About 90 PSI and 4-5 CFM are suitable for most DIY tasks. For heavy-duty tasks like sandblasting, a larger CFM or HP is necessary. | Comes in different sizes based on compressor capacity, tool usage, and project demands. Standard capacities: Small (3-10 gallons), Medium (11-30 gallons), Large (30+ gallons). |

| Portability | Typically bulkier and heavier due to the engine and internal components. | Generally lighter, more compact, and easier to transport, making it suitable for on-the-go projects. |

| Cost | Generally more expensive due to complexity and ability to generate compressed air. | More affordable due to simpler design. |

Major Distinguishing Factor

The main difference between the two is that a compressor actively generates pressurized air, while a tank simply stores and transports it. A compressor uses an engine or motor to compress air, whereas a tank relies on an external source for filling, which is often a compressor itself.

Although they both deal with compressed air, compressors and tanks differ in functionality. A compressor focuses on generating pressurized air, whereas a tank provides convenient storage.

When to Use an Air Compressor

I recommend using an air compressor when you need a continuous supply of compressed air for tasks that require a higher volume and pressure. Here are some situations where I normally use a compressor:

- Pneumatic tools: Compressors are great for powering tools like air hammers, grinders, and nail guns since they require a consistent air supply to function optimally.

- Painting projects: Compressed air ensures a smooth and even finish when using spray guns for painting or staining.

When to Use an Air Tank

I suggest using air tanks if you only need a quick burst of air for tasks. These are the common instances where I find it more fitting to use a tank.

- Filling up tires on cars, bikes, trailers, or ATVs

- Using blow-off tips for cleaning

- Inflating sports equipment like basketballs and footballs

Which Machine Is Better?

An air compressor is much better because of its versatility and broader project scope, whereas an air tank is a good alternative if you need to prioritize portability and quick operations.

A compressor is a more versatile choice for long-term DIY projects, especially since it can compress air for powering pneumatic tools. On the other hand, a tank is more suitable for short-term tasks and on-the-go projects due to its portability.

Related Questions

Do I Need a Tank for an Air Compressor?

An air tank is optional in most cases for a compressor. Air tanks can extend the run time of your air tools and help maintain consistent air pressure. However, smaller air compressors come with built-in tanks or can run tools directly without needing a separate tank.

Can I Fill a Tank Using an Air Compressor?

Yes, you can fill an air tank using an air compressor. To do this, simply connect your compressor to the air tank’s inlet valve, and ensure that the compressor’s output pressure matches the maximum pressure capacity of the tank.

Once connected, turn on the air compressor and allow it to fill the tank.

What Are the Benefits of Using an Air Compressor With a Tank?

Using an air compressor with a tank allows for a more consistent airflow, which can improve the performance of your air tools. Tanks can provide a buffer between the compressor and your tools, reducing the wear and tear on the compressor itself.

Conclusion

Air compressors provide a constant flow of compressed air, making them ideal for heavy-duty tasks. Meanwhile, air tanks offer portability and ease of use. In my experience, both air compressors and air tanks have their advantages, depending on your specific needs for your DIY projects.