4-40 taps are used generally used for tapping stainless steel. If you’re here, you’re probably looking for what size drill bit for a 4-40 tap. It’s important to use the right drill bit size, so the fit and function are correct.

Contents

What Size Drill Bit for a 4-40 Tap?

A 4-40 tap would need a size drill bit of 3/32 inches or a number 43 drill bit. This equates to 0.0890 inches in decimals.

The 4-40 tap is part of the NC thread, just like the 3-48 tap with a drill bit of 5/64″. NC stands for National Course or known also as NC or UNC (Unified National Coarse).

UNC or NC is commonly used in the United States and Canada and is used as means to classify threads. Coarse threads are known for being deeper than fine threads, like the ⅜ taps with 37/64” drill bit and with fewer threads per inch.

Tips for Using Small Drill Bits

Drill Bit Material Matters

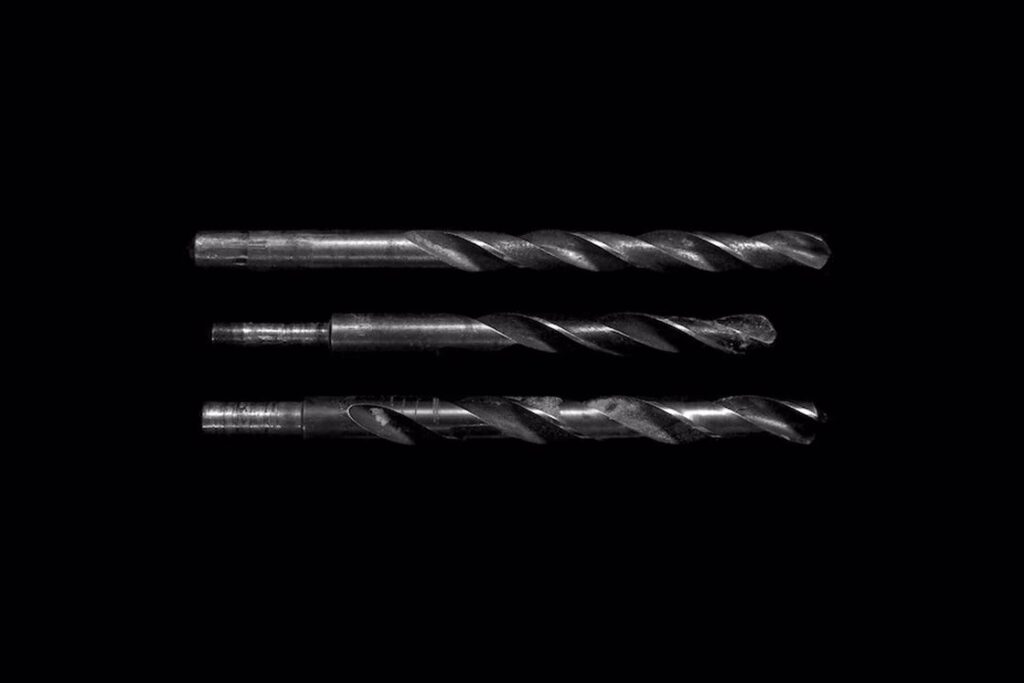

Generally, most drill bits are made for general purposes. This means drill bits can make a decent job drilling holes in most metals. Some drill bits are better for drilling through wood, metal, and concrete.

Most manufacturers usually put the recommended bits to use in their packaging. Therefore, you should have a bit of knowledge of what drill bits to use. Here are some examples of drill bit types and what they can offer:

- Carbon steel can be classified into low and high-carbon steel. Low-carbon steel is the cheapest and is mainly used for drilling softwood and some plastics. High-carbon steel is more robust and can be used for hardwood and soft metals.

- High-speed steel is a popular choice because of its superior quality. It’s mainly used to drill wood and used for CNC drilling.

- Titanium is used for its high corrosion resistance. Titanium is mostly used for repetitive mass production of drilling steel, iron, wood, plastic, and other surfaces.

- Cobalt is mainly used for drilling surfaces that HSS bits can’t. Examples of these are stainless steel and other hard materials.

- A carbide tip is extremely durable. It’s mainly used for drilling fiberglass-reinforced plastic and nonferrous heavy metals.

- Diamond – is one of the toughest materials and is mainly used on the toughest surfaces, such as glass and ceramic.

Lubricate Drill Bits to Make Them Last Longer

Lubrication decreases the friction between surfaces. This means less heat is generated, making your drill bits less compromised when they’re not that heat resistant. It also keeps your drill bits working longer since it coats drill bits with protection against rust and other stuff.

Some surfaces like aluminum, brass, or cast iron don’t necessarily need lubrication to drill properly. It doesn’t always have to be the case as lubrication also offers other things.

Lubrication boosts your drilling speed since there is less friction. If you’ve drilled with and without lubrication, you probably noticed that drilling without lube is slower, especially if you’re not forcing your way through.

Stop Every Now and Then

As I mentioned before, drilling causes friction which in turn creates heat. The heat can dull the drill bit, which you must sharpen more often. The heat may also cause deformities in your workpiece, which you want to avoid.

Rest your drill after drilling 2 to 5 light applications to avoid this. Most people would just let their drill bits rest for a minute or two before resuming to drill again.

Another way is to dip the drill into cold water 5 to 20 seconds after drilling to stop it from heating up. This resets the heat threshold allowing you to drill again without worry of overheating.

Conclusion

The 4-40 tap is used for creating precise holes and for general-purpose drilling. Make sure you use the right drill bit size, which is 3/32 inches, to work properly and last long when applied.