Most people often find adjusting an air compressor pressure regulator quite confusing, starting from what it is and how to go about adjusting the pressure regulator. The process of adjusting the pressure regulator on an air compressor is not as tricky as most people make it out to be.

This article will guide you on adjusting a pressure regulator on an air compressor without facing significant challenges.

Contents

How to Adjust Pressure Regulator on Air Compressor

Despite the process of adjusting the pressure regulator on an air compressor being quite tricky for most people, you can still do it without seeking professional help. The primary function of a pressure regulator is to regulate and control the air pressure of your compressor.

Some air compressors come with multiple regulators that can be adjusted according to their specific purposes.

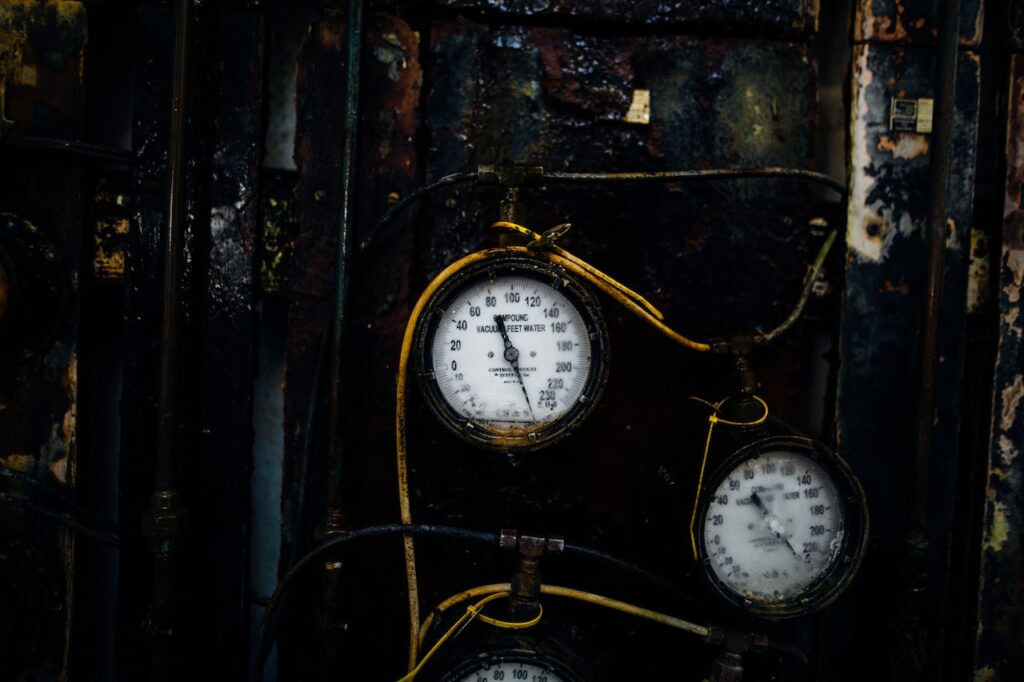

Before getting into the steps to follow when adjusting the pressure regulator on an air compressor, it is essential to know more about it. A pressure regulator comprises three main parts: the regulator body, pressure gauge, and either a T-shaped or simple regulator knob.

When the pressure regulator is activated, the valve inside the regulator’s body comes into action that either increases or decreases the airflow to the air tool.

You should ensure that you have correctly installed your air compressor by following the settings in its manual since different air compressors have different instructions for operation. Below are some of the steps you can follow when adjusting the pressure regulator on your air compressor:

Switch on Your Air Compressor

The first important step is switching on your air compressor after you have connected it to a power source. Turning on an air compressor varies from one gadget to another. Various air compressor models exist despite having similar basic features. Ensure that the power switch is indicated as off before plugging the compressor in to avoid the risk of short-circuiting.

Connect the cord and then turn the switch on.

Allow the Tank to Fill

Once you have plugged the air compressor into the switch and turned the power on, wait for the tank to fill with air until you hear a hissing noise. The noise is expected since it indicates that the tank is now filled with air. Filling up an air compressor with air usually takes a short time to do so.

For instance, a tank with around 125 to 135 pounds per square inch (psi)capacity will take about five minutes to fill with air. A larger capacity tank will take longer to fill with air, while a smaller tank will fill up much faster.

Ensure That the Tools Are Compatible

Compatibility in this context refers to per square inch compatibility since you need to ensure that your tools are compatible with your air compressor. Suppose you are using a device with a higher pressure rating than your compressor. In that case, you will have to look for an air compressor with a corresponding or higher psi capacity.

However, if your tools have a lower psi capacity, they are perfectly safe to use with your compressor.

When your tools are not compatible with your air compressor, they can damage your devices and the air compressor. Incompatibility between equipment might cause injuries arising from pressure buildup between the air compressor and air tools.

Connect the Appropriate Tool and Hose Pipe

Once you have ensured that your tools are compatible for safety purposes, you can now connect the air hose and the air tool. You can then connect the air hose to the air compressor. The port is used to connect the air hose and the air tool.

The process of connecting the air hose to the air tool differs from one air compressor to another. It is, therefore, essential to refer to the user manual for the appropriate instructions for your air compressor.

Adjust the Pressure Regulator

The final step of adjusting the pressure regulator on your air compressor is commenced by first locating the knob on your pressure regulator. For most air compressors, the knob is usually located on the right side of the air compressor.

To raise the pressure of such a compressor, you may need to turn the knob clockwise. Let the pressure increase until it has reached your preferred level. Once at your desired level, push on the knob to lick it. To decrease the pressure level, you simply need to turn the knob anticlockwise.

However, the location of the knob differs for different models of air compressors meaning that they might require a different action from the one mentioned above.

The knob has a locking mechanism that allows you to maintain your chosen pressure level. The locking mechanism helps in preventing accidents and equipment failure. Equipment failure might arise from unregulated rising and falling of pressure levels. To unlock the knob, pull on the knob and vice-versa to lock the knob.

How Does a Pressure Regulator Work?

The pressure regulator controls air pressure through the use of a large screw. This screw also called a set screw, controls airflow in an air compressor. Springs attached to the main tubes of a set screw help regulate the air pressure. Turning the control knob clockwise compresses one of the springs, placing a load on the diaphragm assembly.

The diaphragm, in turn, pushes down on a valve that allows the flow of air from the inlet port to the outlet port. A spring within the valve closes the passage between the two ports once the pressure on the two sides is equal. Greater air demand at the outlet port forces the valve to open, allowing more air in and equalizing the air pressures.

This process is repeated constantly, allowing for the maintenance of a constant pressure level at the outlet port.

Conclusion

Despite the process of adjusting the pressure regulator on your air compressor being a bit complex, this article seeks to help people to change it with a bit of ease and effectively. The five essential tips mentioned also help ensure that safety is maintained while adjusting the pressure regulator yourself.

Learning these essential tips will enable you to effectively increase or decrease the pressure in your air compressor like a professional. While at it, do not forget to use your manual to make the process as smooth as possible!